CAPILLARY HOSES

- model :

- Capillary Hoses

EC Freon LFR5 thermoplastic hose is used in refrigeration systems for both the fixed plants, and the automotive1 industry. The intense research on new materials has allowed to develop a product that can substitute traditional copper piping, offering the advantage of flexibility and ease assembly, while maintaining excellent strength and low permeability to refrigerant gases (including CO2). 1) Service stations for the recharge of refrigerant gas and the maintenance of A/C systems.

Product Description

EC Freon LFR5 thermoplastic hose is used in refrigeration systems for both the fixed plants, and the automotive1 industry. The intense research on new materials has allowed to develop a product that can substitute traditional copper piping, offering the advantage of flexibility and ease assembly, while maintaining excellent strength and low permeability to refrigerant gases (including CO2). 1) Service stations for the recharge of refrigerant gas and the maintenance of A/C systems.

Technical features • LETT Freon LFR5 thermoplastic hoses represent an innovative alternative to the traditional copper tubing for applications in refrigeration plants and automotive industry. Flexibility, light weight, vibration damping and ease assembly are the main features of these thermoplastic hoses.

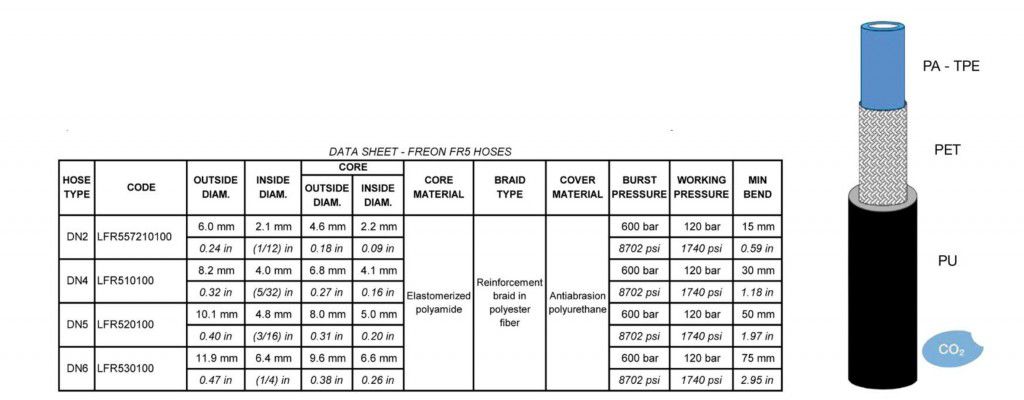

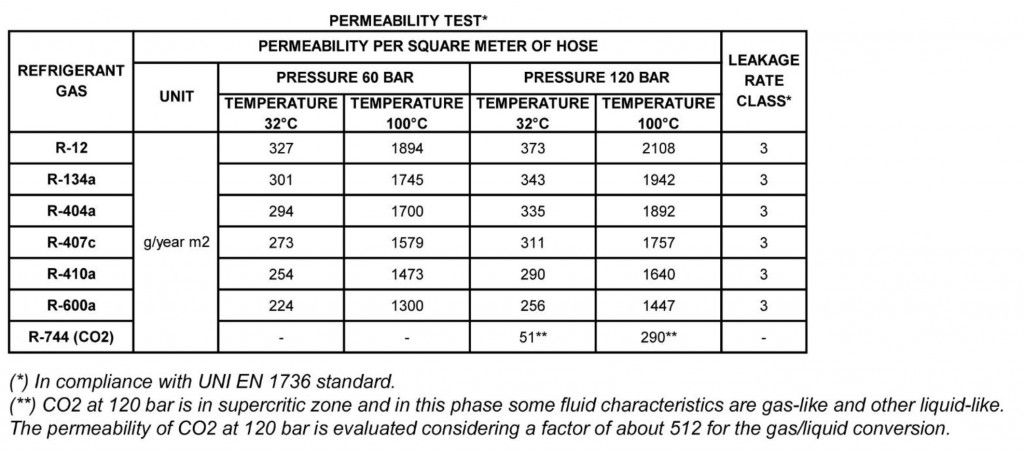

• The research in the field of plastics has produced a particular alloy of polyamide (PA) and thermoplastic elastomers (TPE). This innovative material combines the excellent mechanical properties and low gas permeability of polyamides, with the high flexibility of elastomers, without having recourse to plasticizing additives. Despite of its low density, the elastomerized polyamide provides an excellent barrier to refrigerant gases (R-22, R-134a, R-404a, R-407c, R-410a, R-507, R-600a, R-744) and an excellent chemical resistance to lubricating oils, typically mixed with the refrigerant (e.g. PAG oils, mainly used in automotive industry, or POE oils, spread in fixed installations).

• “F-Gas” directives (2006/40/EC and 2006/842/CE) require the use of refrigerants with low environmental impact (GWP <150, Global Warming Potential). Carbon dioxide used as refrigerant (R-744) has a GWP = 1, it is non-flammable, has low toxicity, is readily available and low cost. However, CO2 requires pressures about 10 times higher than a conventional refrigerant gas. LETT Freon LFR5 thermoplastic hoses have been developed to work with CO2, providing a working pressure up to 120 bar, with a safety ratio of 1:5.

• Internal core of LETT Freon LFR5 hoses is made of elastomerized polyamide. Reinforcing braid in high tenacity polyester yarn (PET) and micro-perforated cover in antiabrasion polyurethane (PU) provide hose a high resistance to pressure and surface abrasion, ensuring performances in accordance with UNI EN 1736 standard.

• Working temperature of LETT Freon LFR5 hoses is in the range -45°C to +130°C. Furthermore the directives REACH (2006/1907/EC) and RoHS (2002/95/EC) are met.

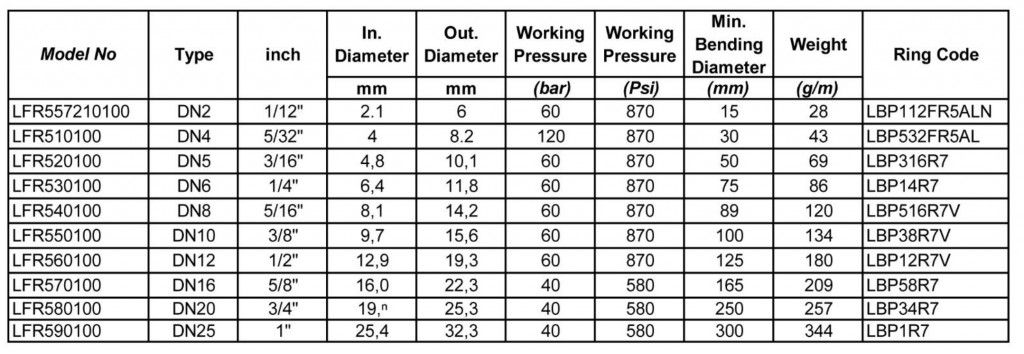

LFR5 SERIES CAPILLARY HOSES TECHNICAL SPECIFICATIONS

Technical-constructive features: Internal core in polyamide, reinforcement with a polyester fiber, exterior covering in micro perforated polyurethane antiabrasion. Applications: CAPILLARY LFR5 series hoses have been created for the through flow of R22, R134A, R404, R407, R410, R507 refrigerants and CO² and relevant POE oils lubricants. Utilization temperature: From -45°C to +130°C Specification: Standards UNI EN 1736, Regulation “REACH” (EC n° 1907/2006), European Directive n° 2002/95/EC “RoHS”.